Imagine an orchestra where every musician must play in perfect harmony to create a flawless symphony. If even one instrument falls out of sync, the entire performance suffers. Manufacturing operations work in much the same way—production activities must be precisely scheduled and synchronized to ensure efficiency. However, unforeseen challenges like equipment breakdowns, material shortages, or changing demand patterns can disrupt workflows, causing inefficiencies and delays.

Now, consider a modern adaptive music system that dynamically adjusts tempo based on real-time input. Oracle’s introduction of Production Scheduling in Oracle Supply Chain Planning Cloud functions in a similar way, enabling manufacturers to review, adjust, and optimize production schedules in real-time while seamlessly integrating with Oracle Manufacturing. This powerful enhancement ensures that production plans remain aligned with

The Power of Production Scheduling in Oracle Supply Chain Planning Cloud

Oracle’s Production Scheduling transforms manufacturing execution by offering:

- Real-time Schedule Adjustments: Dynamically revises schedules based on production constraints, equipment availability, and material supply.

- Seamless Integration with Oracle Manufacturing: Automatically releases production signals to shop floor execution, ensuring synchronized operations.

- Intelligent Prioritization: Optimizes job sequencing based on due dates, demand fluctuations, and resource efficiency.

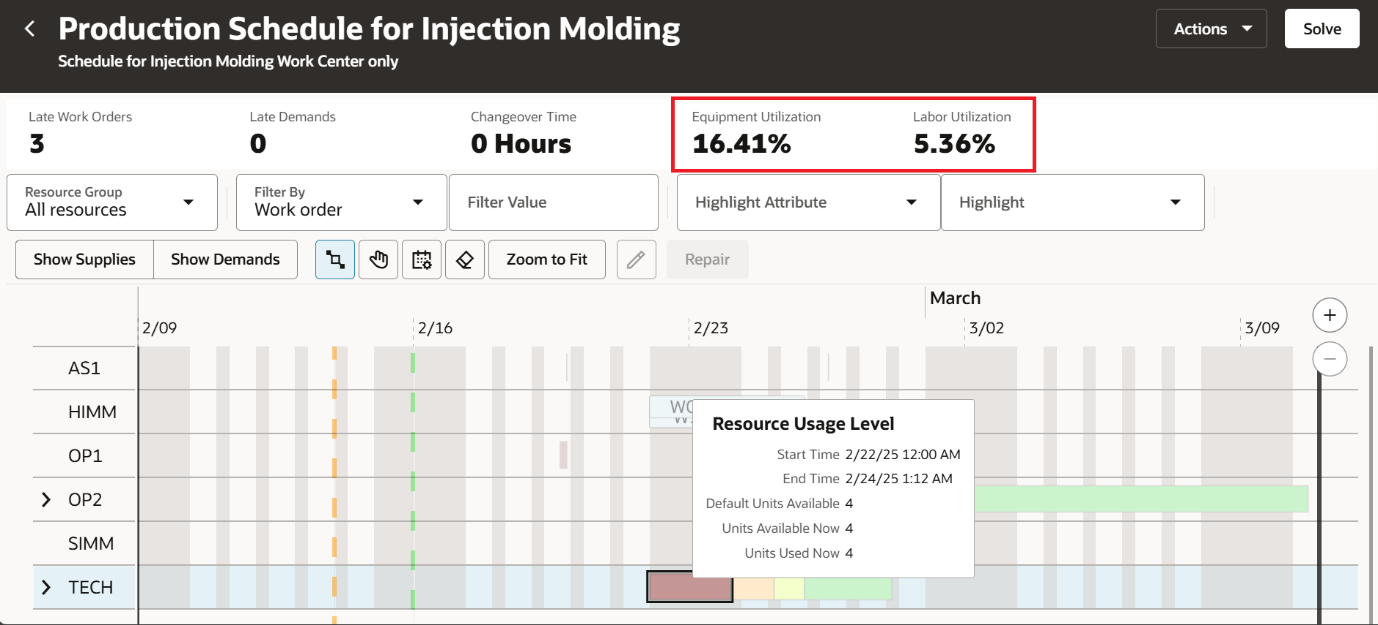

- Enhanced Visibility: Provides a holistic view of production loads, work center capacity, and dependencies for proactive decision-making.

What we understand from the above?

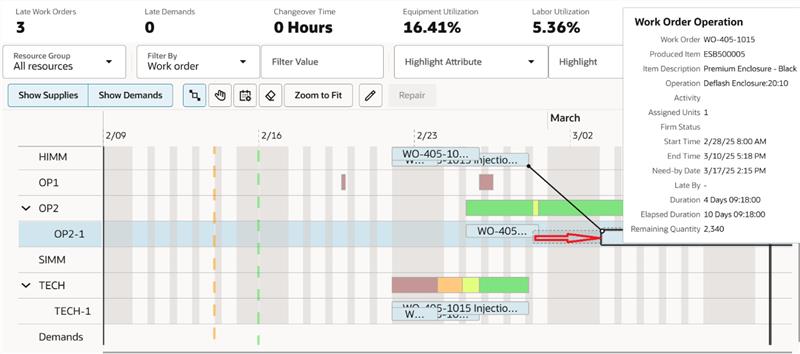

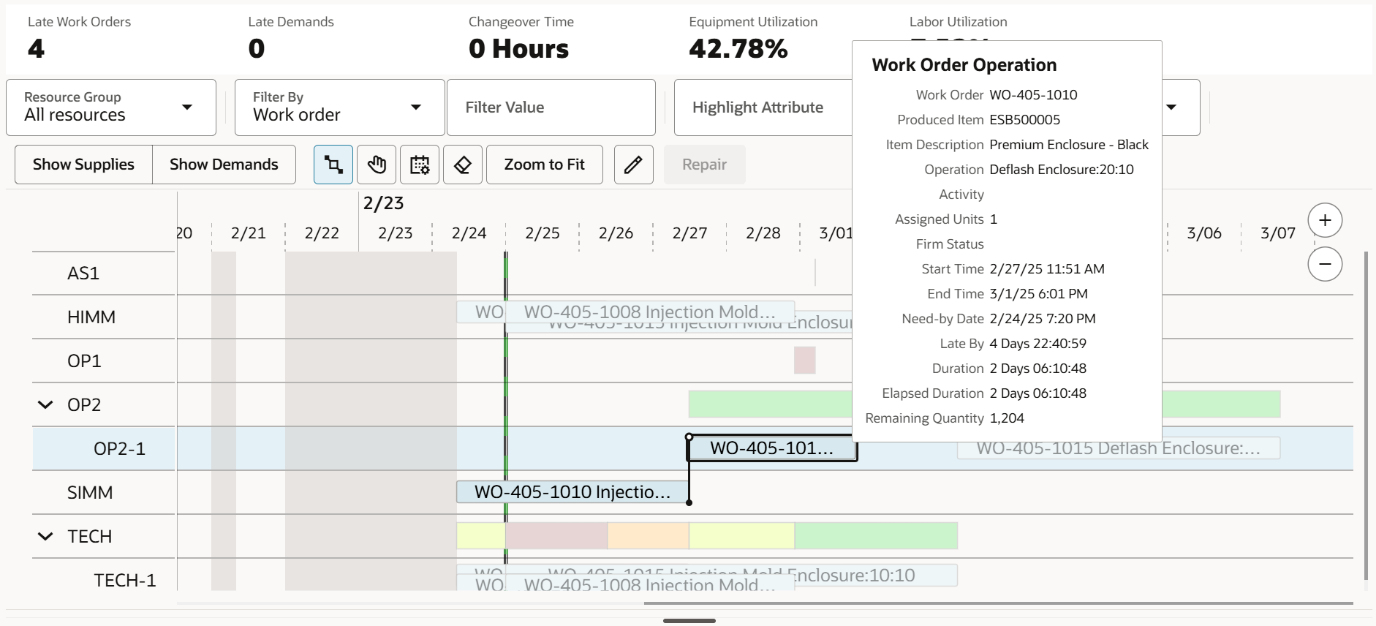

Production scheduling in Oracle Supply Chain Planning Cloud enables planners to continuously review and fine-tune schedules through an intuitive interface. Key capabilities include:

- Automated Schedule Generation:

- System-generated production schedules based on demand forecasts, material availability, and constraints.

- Capacity-aware scheduling ensures optimal utilization of work centres and machines.

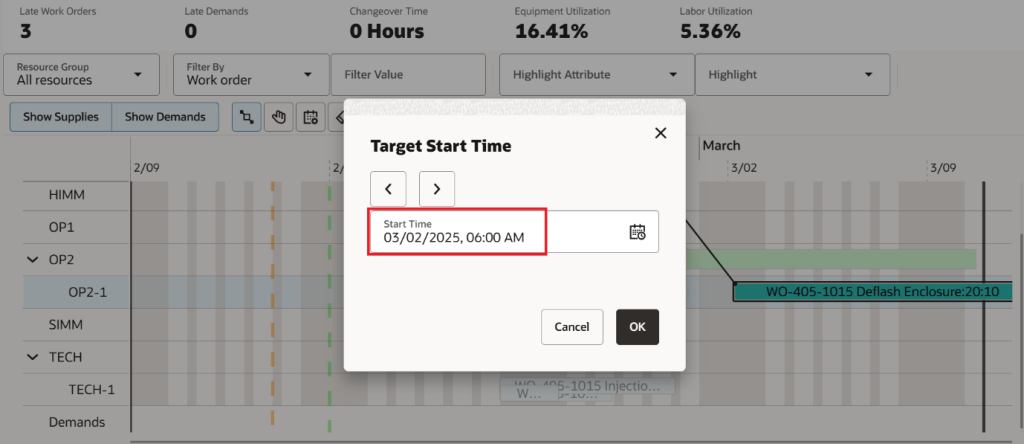

- Interactive Adjustments:

- Drag-and-drop functionality to reprioritize jobs and reallocate resources as needed.

- Scenario modelling to evaluate the impact of changes before finalizing updates.

- Real-Time Constraint Resolution:

- Identification of bottlenecks and proactive recommendations to mitigate delays.

- Adaptive scheduling that considers lead times, machine downtime, and labour availability.

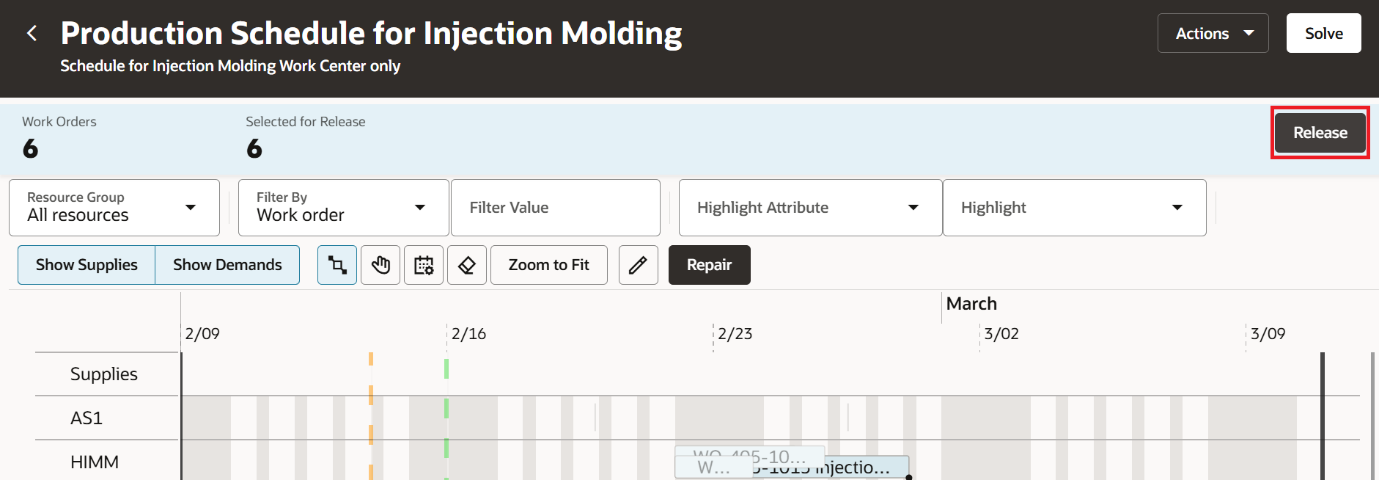

- Automated Signal Release to Oracle Manufacturing:

- Once the schedule is finalized, production signals are seamlessly transmitted to Oracle Manufacturing Cloud.

- Ensures execution teams receive up-to-date job priorities and task assignments.

Conclusion

With the introduction of Production Scheduling in Oracle Supply Chain Planning Cloud, Oracle has reinforced the synergy between supply planning and manufacturing execution, creating a unified, intelligent scheduling solution. This marks a major milestone in cloud-based supply chain management, allowing manufacturers to dynamically optimize schedules, enhance resource efficiency, and seamlessly release production signals to Oracle Manufacturing—all in real-time.

By bridging the gap between planning and execution, this integrated approach eliminates traditional scheduling inefficiencies, enhances shop floor responsiveness, and empowers businesses to meet demand with greater precision and agility.

As manufacturers continue to embrace digital transformation, this powerful combination of supply planning and production scheduling will be a game-changer—driving efficiency, improving on-time delivery, and strengthening supply chain resilience in an increasingly complex and competitive landscape.