Planning is only as good as the assumptions behind it. For decades, businesses have relied on static supplier lead times — numbers set once in the system, rarely updated, and often far from reality. The result? Either excess stock gathering dust in warehouses or constant firefighting with expedite orders when things don’t arrive on time. Both are expensive.

Oracle Fusion Cloud: Changing the Story

Oracle Fusion Cloud changes the story with Lead-Time Insights AI – an intelligent companion that sees beyond assumptions, listens to your data, and whispers the truth about where time is lost and where it can be regained.

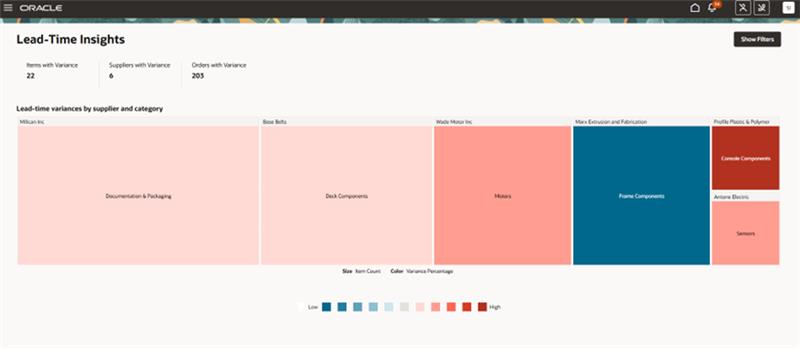

Instead of drowning in spreadsheets, planners are greeted by a Treemap Overview. Each supplier and item is a block: the bigger the block, the bigger the impact; the warmer the color, the greater the variance.

It’s more than data. It’s a landscape of time itself showing planners not just where problems exist but where opportunities lie.

The Cost Angle: Where Savings Appear

When AI surfaces real supplier performance, planners can reduce the “extra buffers” that inflate costs.

- If suppliers consistently deliver faster, safety stocks can be trimmed down, lowering inventory carrying costs and freeing up working capital.

- If suppliers consistently deliver slower, procurement can act proactively instead of resorting to costly last-minute expedite orders.

- Over time, the enterprise cuts down both waste and working capital locks, while maintaining service levels.

Industry Verticals Where It Matters Most

Retail & Consumer Goods

Fashion trends fade quickly. Seasonal products have a short shelf life. With Lead-Time Insights, retailers avoid overstocking fast-fashion items by aligning lead times with actual supplier performance. This means fewer markdowns, less clearance stock, and healthier margins, all while ensuring stores are stocked at the right time.

Automotive

Automotive supply chains are famously complex, with tier-2 and tier-3 suppliers feeding critical parts into the production line. A missed delivery can stop production cold. By using AI-driven lead time accuracy, manufacturers can hold less buffer stock while still ensuring continuity. The result: reduced inventory costs across thousands of parts, without jeopardizing production schedules.

High-Tech Electronics

Semiconductors and high-value electronic components come with high carrying costs. Traditionally, companies held weeks of safety stock to offset uncertain supplier lead times. With Oracle Lead-Time Insights, planners identify which suppliers consistently meet or beat commitments. This allows them to reduce buffer stock and free up millions in working capital crucial in a cash-intensive sector like high-tech.

Mini Case: Electronics Manufacturer Unlocks Hidden Savings

A leading consumer electronics company producing smartphones faced ballooning inventory costs. The system assumed a 20-day lead time for semiconductor suppliers, but AI analysis revealed three key suppliers consistently delivered in 14–15 days.

Armed with this insight, planners safely reduced safety stock across multiple product lines, cutting inventory by 15%. The financial impact was significant: millions of dollars in freed working capital, without compromising product availability during peak launch season.

What once looked like a “necessary cost of doing business” turned into an efficiency opportunity unlocked by Oracle’s Lead Time Insights AI.